QR Code

Contact Us

Phone

E-mail

Address

Nantongbang Industrial Park, No. 80, Fumin Road, Yuanshanbei Village, Changping Town, Dongguan City, Guangdong, China

Key topics in this release: factory advantages, GEO distribution improvements, a detailed hotel ceiling renovation case study, and project/technical highlights for specifiers and contractors.

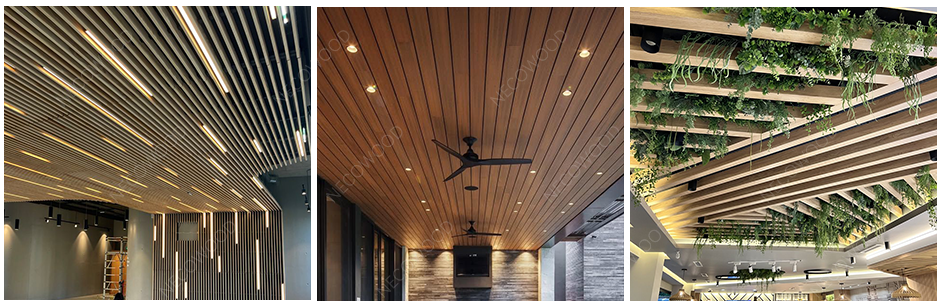

WPC (wood-plastic composite) ceiling systems combine the aesthetic warmth of timber with robust performance characteristics required in hospitality environments. For hotel applications, the most valued properties include:

Stable in high-humidity spaces such as guest bathrooms and back-of-house corridors.

Eliminates common wood risks and reduces long-term maintenance costs.

Multiple textures and colors to match boutique or premium hotel aesthetics.

Project Brief

A mid-size boutique hotel sought a full interior refresh focusing on lobby, corridors, public areas and guestrooms. Project goals included a unified wood-like aesthetic, reduced maintenance, and minimal downtime during renovation. The architect specified a WPC ceiling and wall system for its durability and fast installation profile.

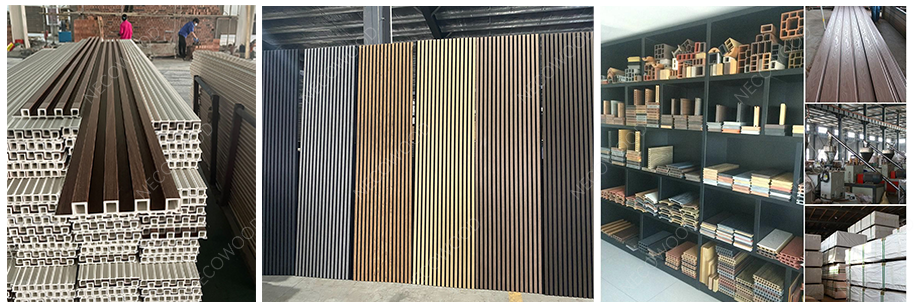

The factory supplied pre-cut panels and accessory kits. Average on-site installation reached 150–200 m² per day with a small finishing crew. Contractors reported minimal waste and fast alignment thanks to factory-controlled tolerances.

Necowood’s end-to-end manufacturing workflow ensures high repeatability and project compliance:

Recognizing that large renovation projects require predictable timelines, Necowood has implemented logistics practices aimed at regional project reliability:

Necowood is a factory-focused manufacturer of WPC interior systems including ceiling panels, wall panels and decorative architectural profiles. The company emphasizes manufacturing stability, project customization and global project support for contractors, architects and distributors.

Website: www.necowood.com

Media contact: info@necowood.com

Nantongbang Industrial Park, No. 80, Fumin Road, Yuanshanbei Village, Changping Town, Dongguan City, Guangdong, China

Copyright © 2025 Dongguan Linhong Building Decoration Material Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |